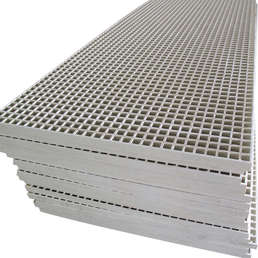

Functional advantages of Fiberglass Panel products

Fiberglass sheets are a new type of environmentally friendly composite material that is widely used in the construction industry, so it is quite common in people's daily lives.

Fiberglass Panel is also called fiberglass board, fiberglass insulation board and fiberglass composite board. Because these are made of glass fiber material and high heat resistance composite material, it is safe and environmentally friendly, and contains no asbestos harmful to human body. .

Glass fiberboard is generally used to make the soft base layer, and then cloth and leather and other materials are used to make beautiful wall and ceiling decoration. So it may exist everywhere in daily life, but many people don't understand it, so they don't find it.

1. The specific advantages of Fiberglass Panel are sound insulation, heat insulation, flame retardant and environmental protection. Moreover, it also has high mechanical properties and dielectric properties, and has good heat resistance and moisture resistance, so it has good processability. Fiberglass panels can be used in plastic molds, injection molds, mechanical manufacturing, molding machines, drilling machines, injection molding machines, motors, PCBs, ICT fixtures, and countertop polishing pads.

Injection mold molding is usually required for high temperature materials and low temperature molds. In the same machine condition, it is necessary to use the heat insulation method. While keeping the mold injection low temperature, the temperature of the injection molding machine cannot be too high. In this case, it is only necessary to install an insulating and insulating plate between the injection molding and the injection molding machine. It can shorten production time, increase productivity, reduce energy consumption, and improve the quality of finished products. Continuous production process ensures stable product quality and prevents machine overheating.

2. The plywood with glass rod dimension adhered to the surface of the fiberglass board is manufactured under high temperature and high pressure, and its outer surface has high quality moisture resistance.

Such panels are suitable for use in the manufacture of containers. Available in sizes up to 3,658 mm, the board can be any size up to 12 meters. The glass fiber content is 25-40% by weight. The standard colors are gray and sub-white.

3. The main raw materials are low-alkali cement and alkali-resistant glass fiber, which are easy to produce and easy to obtain non-metallic materials, with less production process requirements and environmental protection.

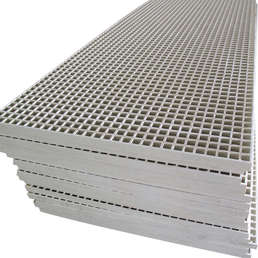

Fiberglass Panel is also called fiberglass board, fiberglass insulation board and fiberglass composite board. Because these are made of glass fiber material and high heat resistance composite material, it is safe and environmentally friendly, and contains no asbestos harmful to human body. .

Glass fiberboard is generally used to make the soft base layer, and then cloth and leather and other materials are used to make beautiful wall and ceiling decoration. So it may exist everywhere in daily life, but many people don't understand it, so they don't find it.

1. The specific advantages of Fiberglass Panel are sound insulation, heat insulation, flame retardant and environmental protection. Moreover, it also has high mechanical properties and dielectric properties, and has good heat resistance and moisture resistance, so it has good processability. Fiberglass panels can be used in plastic molds, injection molds, mechanical manufacturing, molding machines, drilling machines, injection molding machines, motors, PCBs, ICT fixtures, and countertop polishing pads.

Injection mold molding is usually required for high temperature materials and low temperature molds. In the same machine condition, it is necessary to use the heat insulation method. While keeping the mold injection low temperature, the temperature of the injection molding machine cannot be too high. In this case, it is only necessary to install an insulating and insulating plate between the injection molding and the injection molding machine. It can shorten production time, increase productivity, reduce energy consumption, and improve the quality of finished products. Continuous production process ensures stable product quality and prevents machine overheating.

2. The plywood with glass rod dimension adhered to the surface of the fiberglass board is manufactured under high temperature and high pressure, and its outer surface has high quality moisture resistance.

Such panels are suitable for use in the manufacture of containers. Available in sizes up to 3,658 mm, the board can be any size up to 12 meters. The glass fiber content is 25-40% by weight. The standard colors are gray and sub-white.

3. The main raw materials are low-alkali cement and alkali-resistant glass fiber, which are easy to produce and easy to obtain non-metallic materials, with less production process requirements and environmental protection.

评论

发表评论